If you’re looking to upgrade your workshop, a CNC leather cutting machine is a must-have. These machines improve precision, reduce material waste, and save time. Choosing the right equipment matters. That’s why trusting a digital cutting machine supplier like DIGITAL CUTTING MACHINE SUPPLIERS can make a difference. They provide high-quality machines and reliable support. With over 3,000 satisfied customers worldwide, DIGITAL CUTTING MACHINE SUPPLIERS ensures efficient leather cutting for all kinds of projects. Learn how these machines work and what makes them worth the investment.

What Is a CNC Leather Cutting Machine?

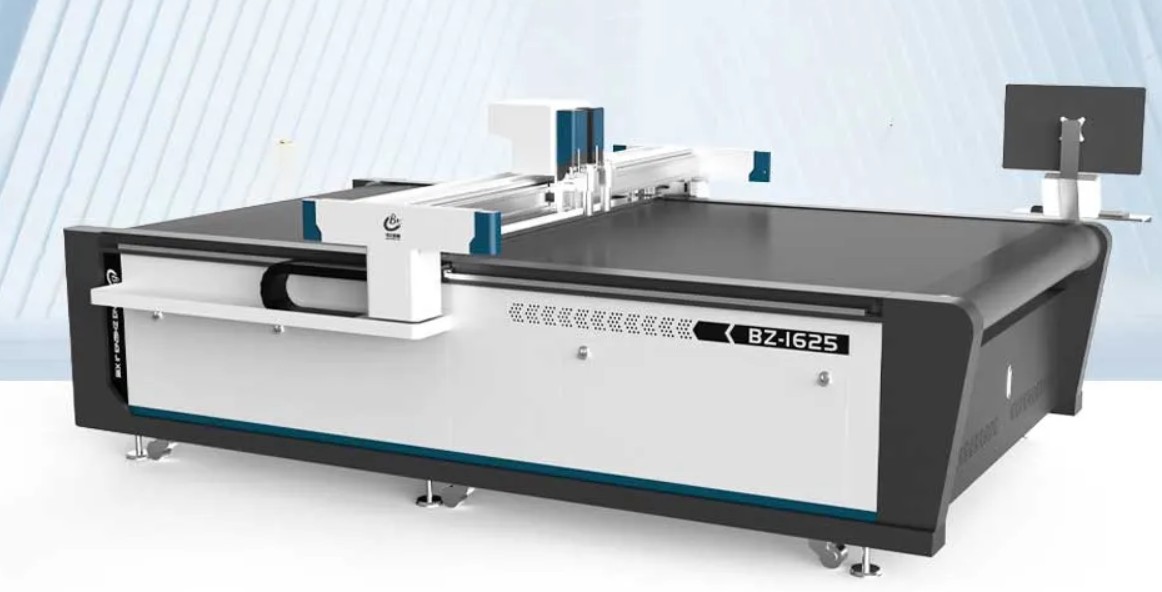

A CNC leather cutting machine is a computer-controlled device that cuts leather into specific shapes and patterns. Unlike manual cutting, CNC machines ensure every piece is precise. They handle thick or soft leather, multiple layers, and complex designs. Most models use a knife or oscillating blade to make smooth, clean cuts without tearing.

For example, a shoe manufacturer can cut 16 layers of leather at once with one machine. This reduces production time and labor costs significantly. Using CNC also means fewer mistakes and less wasted material, which directly saves money.

Why Use a CNC Leather Cutter

Using a CNC leather cutter offers several benefits.

First, precision. These machines cut patterns to the exact millimeter. This is important for products like shoes, handbags, and furniture where every piece must fit perfectly.

Second, speed. Manual cutting can take hours for large batches. CNC machines can cut dozens of pieces in minutes. Some models even offer automatic feeding and stacking, saving workers from repetitive tasks.

Third, consistency. Every cut looks the same, no matter how many batches you run. This is crucial for brand quality.

Fourth, versatility. CNC leather cutters handle different materials like synthetic leather, PU, and fabric blends. This flexibility allows small businesses to expand product lines without extra machines.

How Digital Cutting Machine Suppliers Stand Out

DIGITAL CUTTING MACHINE SUPPLIERS is a reliable provider of CNC leather cutting machines. Their factory spans 50,000 square meters and employs over 200 professionals. They’ve served more than 3,000 customers globally. Their machines hold ISO 9001 certification and support OEM/ODM orders.

They also provide strong after-sales support. Customers can access local technical assistance, lifetime system upgrades, and guidance on maintenance. Whether you’re a small workshop or a large factory, their machines are scalable and practical.

Features to Look For in a CNC Leather Cutter

When choosing a machine, pay attention to features like:

Cutting thickness and layers: Most machines handle 1–11 cm thickness and multiple layers. This is useful for shoe soles or handbags.

Accuracy: Look for machines with ±0.01mm precision to avoid errors in mass production.

Material utilization: Efficient machines reduce scraps and save leather, often achieving 98%+ utilization.

Automation: Machines with automatic feeding and discharging save labor and increase output.

Maintenance and support: Check for warranties, local service, and software upgrades. DIGITAL CUTTING MACHINE SUPPLIERS offers a three-year equipment warranty and lifelong technical guidance.

Pros and Cons of CNC Leather Cutting

Pros:

High precision and clean edges

Faster production with multiple layers

Less material waste

Reduces labor cost and fatigue

Handles complex designs easily

Cons:

Initial cost can be high

Requires electricity and proper setup

Training may be needed for staff

Despite the cons, most businesses find CNC machines a worthwhile investment. Reduced waste and faster production often pay back the cost in months.

Real-World Applications

CNC leather cutting machines are used in footwear, bags, furniture, and automotive upholstery. For example, a sports shoe manufacturer in Brazil cuts multiple layers of leather even in hot and humid conditions. The machine maintains perfect shape without adhesion or errors.

Fashion brands benefit too. Small designers can produce prototypes quickly. They can try new patterns and scale up production without hiring more staff.

Even in furniture, leather CNC cutters save time when making chair seats or car interiors. The precision ensures every piece fits perfectly.

Tips for Choosing the Right Supplier

Always check the supplier’s certification and customer reviews. A good supplier like DIGITAL CUTTING MACHINE SUPPLIERS provides ISO-certified machines and has thousands of satisfied clients.

Ask about support services. Machines need calibration, repairs, and software updates. Lifetime guidance and local maintenance reduce downtime.

Consider your production needs. If you cut multi-layer leather regularly, pick a model that handles thicker material and more layers. If you mostly make prototypes, smaller models may suffice

Verdict

A CNC leather cutting machine is essential for efficient, high-quality leather production. Choosing the right supplier ensures reliable machines, strong support, and long-term savings. DIGITAL CUTTING MACHINE SUPPLIERS stands out for their quality, experience, and service. Their machines suit workshops of all sizes and handle complex designs with ease.

Investing in a CNC leather cutter today can save money, reduce waste, and increase output. Whether you make shoes, bags, or furniture, these machines are practical, precise, and efficient. Learn more about their products and services at https://bangzhengcutter.com/